Fujitsu announces development of the world's 1st technology for bonding single-crystal diamond to a silicon carbide substrate at room temperature

OREANDA-NEWS. Fujitsu Limited and Fujitsu Laboratories Ltd. today announced development of the world's first technology for bonding single-crystal diamond to a silicon carbide (SiC)(1) substrate at room temperature. Using this technology for heat dissipation in a high-power gallium nitride (GaN)(2) high electron-mobility transistor (HEMT)(3) enables stable operations at high power levels. Application of this technology is expected to significantly enhance the performance of weather radars and wireless communications.

Boosting range and power in radar and wireless communications also increases the heat produced by devices, which adversely affects their performance and reliability. This creates a need to efficiently carry device heat to a cooling structure. Single-crystal diamond is known to have good thermal conductivity, but with existing technologies, the argon (Ar) beams used to remove impurities in the manufacturing process create a low-density damaged layer on the surface, which weakens bonding strength. Also, bonding with an insulating film such as silicon nitride (SiN) impairs thermal conductivity due to SiN's thermal resistance.

Now, by protecting the surface of the diamond with an extremely thin metallic film, Fujitsu and Fujitsu Laboratories succeeded in preventing the formation of the damaged layer and bonding single-crystal diamond to a SiC substrate at "room-temperature bonding"(4). Simulations using actual measurements of thermal parameters have confirmed that devices using this technology would lower thermal resistance to 61% of existing ones.

This technology promises GaN-HEMT power amps for transmitters to operate at higher power, and increase the observable range by roughly 1.5 times when applied to systems such as weather radar.

This research was conducted in part with support from the Innovative Science and Technology Initiative for Security, established by the Acquisition, Technology & Logistics Agency (ALTA), Japan Ministry of Defense.

Details of this technology are being presented at the IEEE Semiconductor Interface Specialists Conference (SISC2017), running December 6-9 in San Diego, U.S.

Background

In recent years, high-frequency GaN-HEMT power amps have widely been used for long-range radio applications, such as radar and wireless communications. They are also expected to be used in weather radar that observes localized heavy rains, for example, or in the forthcoming 5G millimeter-band mobile communications protocols. For these types of radars or wireless communications using the microwave to millimeter-wave bands, by raising the output of the GaN-HEMT power amps used for transmissions, the distance that radio waves can propagate will allow the expansion of the observational range of radar while enabling longer and higher capacity communications. This is why GaN-HEMT power amps with higher power output are desirable.

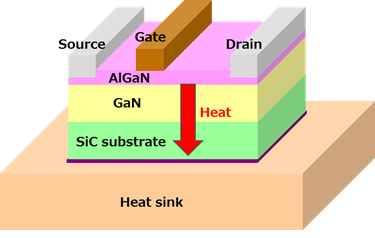

Figure 1: Structure of conventional GaN-HEMT power amp

Figure 1: Structure of conventional GaN-HEMT power amp

Issues

In GaN-HEMT power amps, some of the input power is converted to heat (Figure 1). This heat is dispersed into the SiC substrate, and is carried away by a cooling structure (heat sink). Although the SiC substrate has relatively high thermal conductivity, a material with even better thermal conductivity will be needed for devices with increasingly higher power output to efficiently carry device heat to the cooling structure.

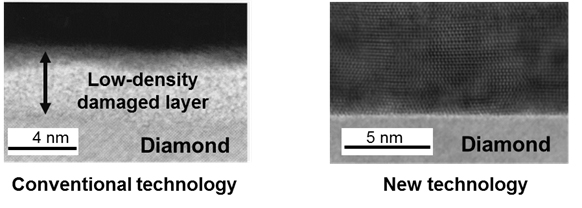

Single-crystal diamond has extremely good thermal conductivity-almost five times that of a SiC substrate-and is known as a material that can efficiently spread heat. In order to bond a single-crystal diamond to a device as a cooling material, normal production processes use an Ar beam to remove impurities, which produces a low-density damaged surface that weakens the bonds the single-crystal diamond can form. Moreover, using SiN or other insulating films for bonding interferes with thermal conductivity due to SiN's thermal resistance.

About the Technology

Fujitsu and Fujitsu Laboratories have succeeded in developing the world's first technology for room-temperature bonding onto a SiC substrate single-crystal diamond, used for high-efficiency cooling of GaN-HEMT power amps. These two hard materials have different coefficients of thermal expansion (Figure 2).

To prevent the Ar beam from forming a damaged layer on the diamond surface, the companies developed a technique that protects the surface with an extremely thin metallic film before it is exposed to the Ar beam. In order to ensure the surface is planar, for good bonding at room temperature, the metallic film is held to a thickness of 10 nm or less. This technology was confirmed to prevent the formation of the damaged layer on the diamond surface after Ar beam exposure (Figure 3), resulting in improved bonding strength and single-crystal diamond bonded at room temperature to a SiC substrate for GaN-HEMT.

Figure 3: Diamond cross section after Ar beam exposure

Figure 3: Diamond cross section after Ar beam exposure

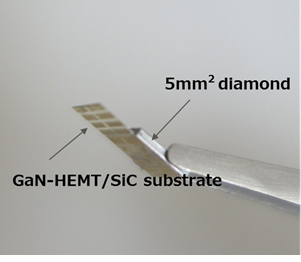

Figure 4: A GaN-HEMT/SiC substrate with diamond bonded using this technology

Figure 4: A GaN-HEMT/SiC substrate with diamond bonded using this technology

Комментарии